Pre milled Abutment | Edison Medical™ - Dental Implant Bay

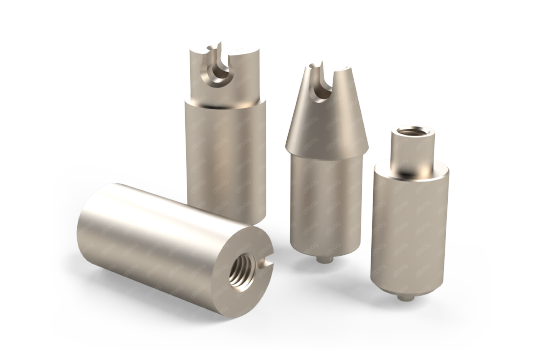

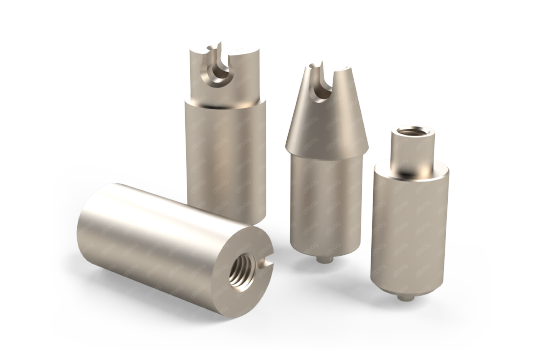

Pre-milled Abutment

Maximizing your in-house milling efficiency.

The freedom of versatility

Edison Medical’s selection of pre-milled blanks are milled from high-grade titanium and available for regular, narrow and wide platform interfaces. Together with your in-house milling equipment, creating a customized abutment is both fast and precise. The possibilities for milling the most tailored abutment for your patient are vast with EM’s portfolio of pre-milled blanks designed for use with a range of implant systems, including Nobel Active®, Neo Biotech®, Megagen® and Astra®.

Pre-milled abutment blanks: Adaptability to every scenario

Pre-milled abutment blanks are mechanically manufactured titanium blanks customized by the periodontist or dental implantologist using in-house milling equipment. The initial investment of milling equipment, while substantial, truly earns its way, with both the return on investment per abutment, and the value of a customized piece for each patient. Milling abutments in-house is efficient and versatile, putting complete design control in the hands of the dental professional.

Once the platform width (either regular, narrow or wide) of the abutment blank is chosen, a few more pieces of information are needed in order to produce a customized abutment: the implant system diameter, cuff height, interocclusal height and angulation. The in-house milling system can then be used to create an abutment with the necessary geometry and angulation tailored to the patient.

Appropriate use of pre-milled abutment blanks

Using pre-milled blanks for in-house milling is a viable option and in many restoration scenarios. Choice of material is paramount, as is that material’s quality. Edison Medical manufactures its pre-milled abutment blanks from the highest-grade polished titanium (Ti-6Al-4V ELI) to provide to each implant system an abutment that features optimal physical properties, mechanical properties and biocompatibility.

Indications

Pre-milled abutment blanks are indicated in all conditions for both final and temporary abutments, and both single-unit and full-arch restorations. See contraindications below.

Contraindications

Several contraindications exist for the use of pre-milled abutment blanks. Contraindications include insufficient interocclusal space, required splinting of more than three implants within a single quadrant, required angle correction of greater than 15°, and when the collar height is less than 1 mm below the gingival margin.

Pre-milled abutment blanks: Weighing the pros and cons

The use of pre-milled abutment blanks provides a valuable return on your in-house milling investment. The process is highly efficient and time-saving, both by reducing the number of needed visits and by quickly producing a final abutment. The procedure of creating an abutment in-house is minimally invasive, as most preparation is done outside the mouth. The customizable nature of these abutments can promote improved healing over stock abutments by creating the most natural emergence profile between implant and prosthesis. It can also improve soft-tissue support resulting from customized contour design of the abutment, which promotes optimal healing and strength of the peri-implant tissue.

While in-house milled abutments may not be appropriate for some scenarios based on the patient’s oral environment, from a practical standpoint there are few disadvantages. The most discussed issue regarding pre-milled blanks is their cost, as there is a significant initial investment necessary for the in-house milling equipment. However, the pricelessness of an entirely customized abutment should not be overlooked.

What is a pre-milled abutment?

A pre-milled abutment is a mechanically manufactured post that attaches to the superior portion of the implant where it protrudes through the gingiva, and on which a restoration is fitted. The pre-milled abutment allows dentists, implantologists and prosthodontists to use their in-house milling equipment to produce a customized abutment for each patient. The most common material used to fabricate pre-milled abutments is titanium, although cobalt-chrome (CoCr) is also currently gaining popularity.