Dental Implant Abutment | EM™ - Dental Implant Components

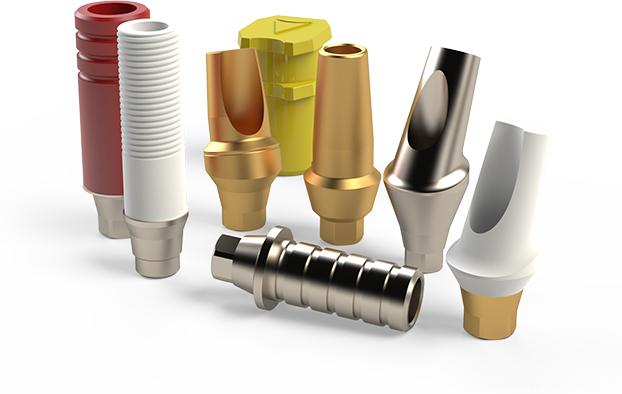

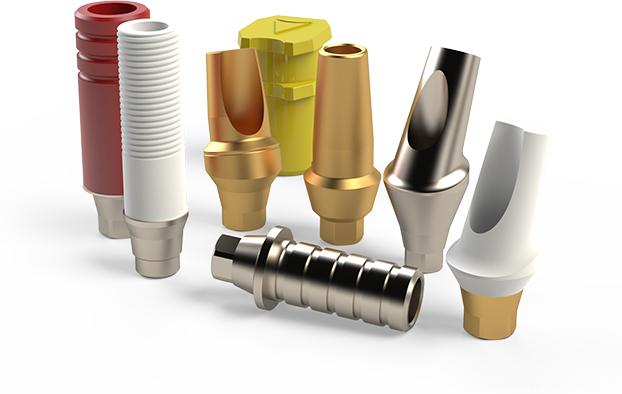

Dental Implant Abutments

Find the dental abutment you need at Edison Medical. Every time.

The dental abutment serves as the mechanical interface between implant and restoration. Dental abutments are manufactured as either an individual piece that screws into the implant after being placed into the patient’s jaw or as an integrated part of the implant itself.

Edison Medical’s range of dental abutments are stand-alone pieces, allowing for a more tailored fit of implant system for each patient’s individual scenario. Choosing high quality materials, proper connection geometry that does not allow unintentional abutment micromovements, and optimal interface design all impact the success of osseointegration.

EM’s selection of temporary, standard, anatomic, castable, transfer, scan, and healing abutments will provide you with a superior quality abutment solution for your dental practice.

Raw materials: The starting point of prosthetic system success

Edison Medical carries the finest raw materials available on the market for standard dental implant abutments. We invite you to explore the benefits of titanium, zirconia, PEEK and cobalt-chrome (CoCr) below to help choose the right material for your practice:

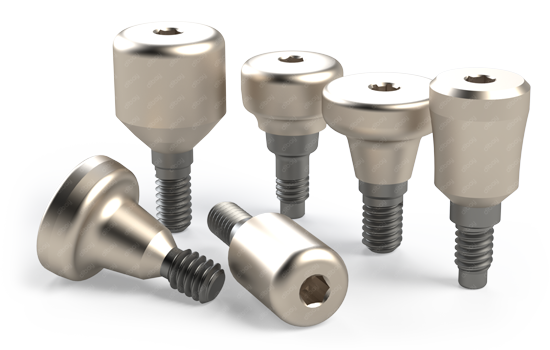

Titanium

Titanium made its debut as a revolutionary workhorse material in the mid-20th century, when the aerospace industry began using it regularly for its impressive and ideal properties of high resistance to corrosion, high strength-to-weight ratio, and light weight.

Today titanium is still regarded by the dental industry as one of the most reliable base materials, due to its unique physical and mechanical properties and high biocompatibility, which make it an ideal material for long-term placement in both biological and oral environments.

Edison Medical titanium abutments are produced from the highest-grade Ti-6Al-4V ELI polished titanium and routinely undergo compression and fatigue tests in order to maintain FDA-cleared status and to ensure optimum strength and accuracy of every product.

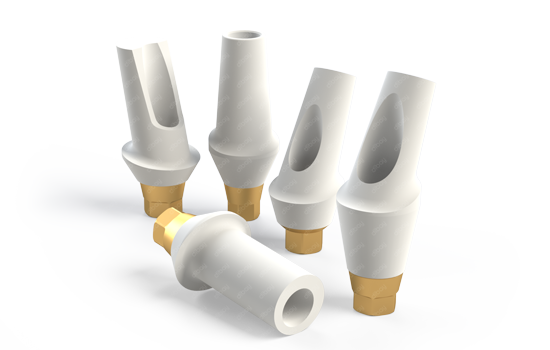

Zirconia

Zirconia abutments are considered to be the ‘gold standard’ when it comes to esthetic results. This is particularly true with patients whose gingival tissue is thin and would otherwise allow light to penetrate through the tissue, exposing the dark metallic hues of a titanium or other metal abutment.

Not only is zirconia an esthetic Wunderkind, but it is also highly biocompatible and features favorable mechanical and microstructural properties. Zirconia experiences less biofilm accumulation compared to titanium, and is a good alternative solution to titanium for patients who are at risk of metal allergies.

The disadvantage of zirconia is that it is a much more brittle material than titanium, which causes it to degrade over time in the oral environment due to temperature and mechanical force, which can ultimately result in loss of mechanical properties of the abutment.

Edison Medical overcomes this by equipping its zirconia abutments with a titanium base — the optimal solution to gain full benefit of zirconia as an abutment, while featuring the strength of titanium, allowing dentists to apply necessary torque when tightening implant abutment screws.

PEEK

Esthetic management and final esthetic quality are, in modern dentistry, considered crucial considerations to the final implant system. Enter PEEK (polyetheretherkeytone), an organic synthetic polymeric material. PEEK's natural color is similar to that of a tooth, making the material an attractive option for use in your implant situations in which esthetics hold a high priority.

Notable advantages of PEEK over titanium include less surface accumulation of biofilm and reduced risk of such common side effects as marginal bone loss and the recession of soft tissue during the initial post-operative healing phase.

Being a newer material to the dental implant market, there is still research needed to improve PEEK’s efficacy and potential in the implant system. Researchers are working to modify and improve the PEEK surface to enhance biocompatibility, proliferation, and cell adhesion, so that it will exhibit similar properties to that of titanium, which, when properly seated has been found to provide a more impervious crestal seal than that of PEEK. Researchers are optimistic that these surface modifications will provide PEEK the potential to compete with titanium regarding their physical properties in the future.

Castable and UCLA abutments: Cobalt-chrome

Edison Medical’s range of UCLA abutments are produced with a hex base of either cobalt-chrome (CoCr) or titanium, which are the two best options in their category. While both perform incredibly well in terms of physical and mechanical properties, cobalt-chrome is fundamentally a much easier material to work with than titanium in terms of precision and getting the intended, accurate result out of the milling process.

Over recent years, CoCr has replaced gold as a leading castable abutment material due to its lower cost and lower density. Among the many differences between cobalt-chrome and titanium, CoCr is effectively a harder material, which makes for a much more precise surface interface of the final abutment.

The right fit: Connection geometry and interface design

Your implant system’s joint stability relies heavily upon the implant-abutment interface and its geometrical quality of fit, which directly depends on the proper choice of the combination of implant connection and abutment. With a wide selection of abutment diameters, heights, angulations and materials, Edison Medical aims to provide endless options to solve even the most complex edentulous cases.

Macroscopic levels of design on the abutment surface, as well as microscopic surface topography also play a major role in long-term success of dental implants. Each abutment that Edison Medical offers has been designed with the intention of facilitating a healthy tissue presence around the implant-abutment interface.

Edison Medical ensures precision and quality in its abutment geometry and surface: the production process is not only meticulous down to the surface of every thread on the abutment surface itself, but every abutment also sees substantial machine time, ensuring that the final product has maximum tolerance and is prepared to last a lifetime.

Unwavered quality: Relying on Edison Medical’s dental abutments

Edison Medical is the only marketplace online where you can find such an extensive range of dental implant abutments designed for use with more than 70 dental implant systems, including all major implant systems.

Edison Medical employs the finest raw materials for every abutment based on the intended use and function of that abutment: titanium, zirconia, PEEK, and cobalt-chrome (CoCr) provide the base for a product quality that stands above the rest. Each abutment is packaged with its respective screw that facilitates a perfect fit.

As the implant industry has evolved over recent years, so have the number of emerging dental implant providers, all with a common goal of taking part in the booming dental implant industry. What sets Edison Medical apart from the rest is our all-encompassing solution to simplify the marketplace: one company that provides the most extensive variety, highest quality, most competitive prices and the lion’s share of across-brand usability options.

What is a dental abutment?

A dental abutment is one of several components of a dental implant restoration that serves as the connection between the dental implant and the prosthesis. It is made from a durable, biocompatible material which is most often titanium, but one can also find abutments made of surgical-grade stainless steel, zirconia, cast gold, and polyetheretherketone (PEEK). The abutment also enables the prosthesis to be switched out without needing to also remove the implant and disrupt the healed tissue around the implant site.